Some Technical data and references are included below however if extra specific Technical data is required please contact us.

Technical data

- Building with Earth Bricks and Rammed Earth in Australia ISBN 0-9756036-0-4

- Earth Builders Association of Australia

- AS 3959 – 2009 Construction of Buildings in Bush Fire Prone Areas

Rammed earth walls

Meet the requirements of AS3959 – 2009

Have a 4 hour fire rating (refer NBTC report No. 1839.) making them ideal for partition walls in duplex and multi-unit building projects.

Compressive strength

Characteristic compressive strength of our walls well exceed the BCA requirements of not less than 2 Mpa, normally 7Mpa.

Acoustic Properties

Sound transmission class 57. Refer. NBTC report No. 1840.

Architects, designers and building practitioners

We often have enquires requesting a referral to architects, designers and building practitioners in different areas across the state of Victoria. If you specialise in the area of unique sustainable construction, we encourage you to contact us to discuss promoting your services.

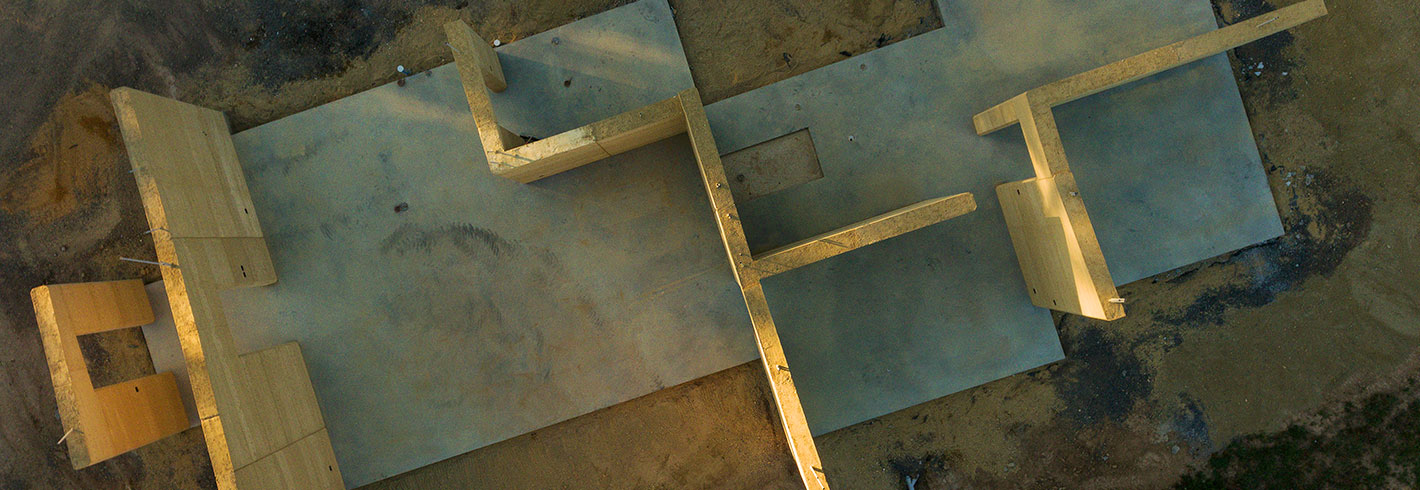

How Rammed Earth Walls are Built

To build Rammed Earth walls, specialised formwork is set up according to the plan of your home, or walls to be built.

1. A soil/gravel mixture which requires less than 20% Clay content is mixed with 8 – 10% Cement and a waterproofing compound.

2. Water is added and mixed to an even consistency, often utilising a Skid Steer loader.

3. The Soil mix is hand shovelled into the formwork and compacted in layers. Data, electrical conduits and wall boxes and plumbing are position in place as the walls are built, as chasing into Rammed Earth walls afterwards will not be visually appealing.

4. Each layer is compacted with a Pneumatic Tamper and the process is repeated. More formwork is fixed and so the process continues until the top of the wall is reached.

5. All structural members required for supporting earth over windows and door openings as well as a roof tie down system are installed during the wall construction process. The type and size of these is influenced by the design of the building.

6. Rammed Earth walls are left in form for approx. 12 hrs before the formwork is removed to reveal a wall of unique beauty that will stand for generations to come.

7. When cured, these will be sealed with a clear sealer to stop dusting of the walls. The sealer is only required once on the internal surface of the walls and approximately every 25 yrs externally.

8. During the design phase it is important to ensure that vertical wall increments are in 300mm vertical increments- for example: window sill heights, door and window head heights and wall top heights.

We are able to build curved walls raked walls and angled walls as well as specialised niches etc.

Contact us to discuss your project.